HeatX is a Nano Surface Treatment that Prevents Fouling and Corrosion, Preserving and Prolonging Optimal Thermal Transfer.

Don't pay the thermal price. HeatX Benefits:

HeatX Customers

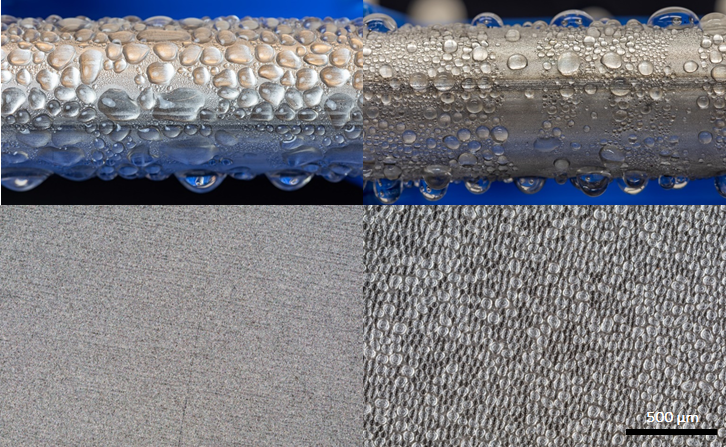

HeatX Technology

HeatX is nano-structured surface treatment technology that enables heat transfer surfaces to effectively repel fouling and protect against corrosion while maintaining thermal transfer properties.

-

Improves heat transfer performance efficiency by repelling fouling and mitigating corrosion

-

Greatly extends typical maintenance intervals, reducing operational costs and downtime

-

Maximizes exchanger performance, reducing your carbon footprint and maximizing output

Power Plants

A majority of electricity production in the U.S. and world is generated from thermal power plants which produce electricity by using heat (burning fossil fuels such as natural gas, oil, coal, biomass, etc.) to turn water to steam which, in turn, drives turbines to produce electricity.

-

HeatX saved Hawaiian Electric Company (HECO) an estimated $1.5 million in replacement energy generation over 5 years per heat exchanger,

-

HeatX extended heat exchanger service frequency 10x from 6 months to 60 months.

Refineries

Italian energy firm Eni S.p.A. and Oceanit presented the results of a collaborative HeatX pilot program at ADIPEC 2021, which demonstrated HeatX's ability to reduce annual emissions from the Eni S.p.A. Alaska Nikaitchuq upstream facility by 17,000 tons of CO2 annually.

-

HeatX demonstrated a 97% reduction of fouling at a refinery comparing a HeatX-treated unit with an untreated control unit.

-

HeatX reduced the corrosion rate by more than 36x while also completely arresting the formation of corrosion pitting, tube fouling, and erosion of the tube interior.