Advanced Monitoring and Prescriptive Maintenance

Empowering Data Driven Decisions

ThermAI's Hybrid Twin™ for Advanced Monitoring and Prescriptive Maintenance is a powerful operational excellence tool that supports data driven decision making in refinery operations, maintenance, production planning, profitability and environmental sustainability.

Advanced Monitoring of Heat Exchangers

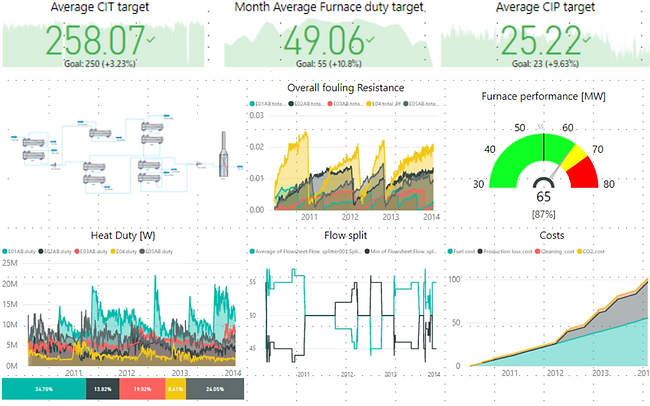

ThermAI Advanced Performance Monitoring™ provides unprecedented insights into Heat Exchanger network thermo-hydraulic performance, leveraging the power of ThermAI Data Studio's™ fouling prediction capabilities:

Individual Heat Exchangers:

- Thermal performance (including fouling resistance, heat duty loss vs. clean)

- Hydraulic performance (ΔP vs ΔP clean)

- Key operating variables (e.g. shear stress, velocity, film temperature, wall temperature, Re number, etc.) vs. clean conditions

- Heat exchanger contribution to network performance

Overall Network:

- Actual furnace inlet temperature vs. clean conditions (i.e. furnace inlet temperature if all exchangers were clean)

- Predicted pressure drop increase vs. clean conditions (i.e. if all exchangers were clean)

- Assessment and detailed breakdown of economics and other KPIs

- Advanced visualization plots

Prescriptive Maintenance and Operations Improvements

Periodic cleaning is a common and often necessary strategy to maintain the performance of heat exchangers over long operation. However, deciding which heat exchanger to clean, when to clean it, and how to clean it (e.g. mechanically or chemically) is a non-obvious task which often relies past experience and simplistic performance indicators, rather than economic drivers and specific Key Performance Indicators (KPIs).

ThermAI Data Studio's™ advanced capabilities include:

Predictive Maintenance:

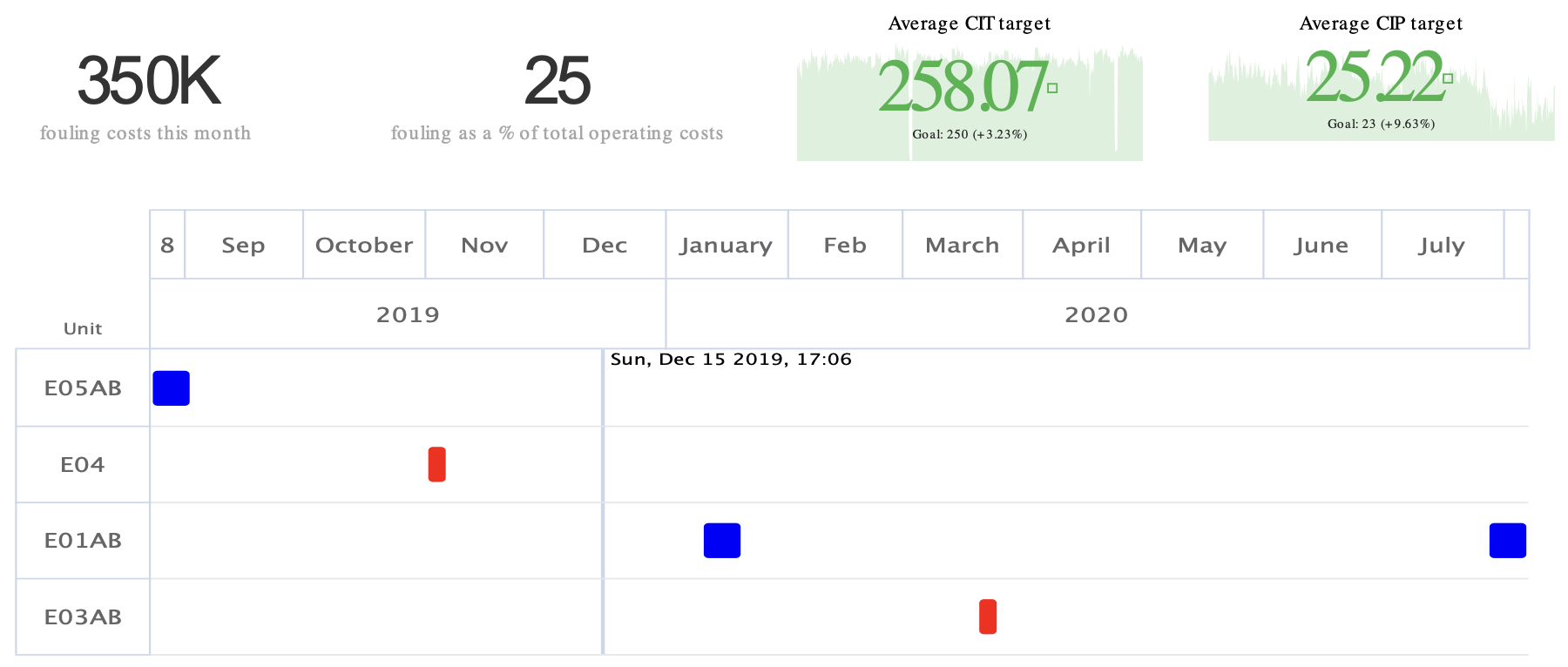

- Identification of the best heat exchanger to clean, and when to clean over an extended period of time

- Clean on opportunity: identify the best heat exchanger to clean today or during a short-term unplanned shutdown in order to minimize furnace duty

Prescriptive Maintenance:

- Evaluation of trade-offs between different cleaning methods (mechanical, chemical, thermal cleaning)

- Condition-based: how long a cleaning action needs to last, depending on the conditions of the asset (to minimize downtime)

Operations Improvement:

- A detailed analysis of operations and performance of the previous month

- Performance Prediction (thermal and hydraulic) for the overall network over the next few months of operations with a Base Case Scenario (current operation plan – e.g. cleaning schedule, flow splits), in particular trends towards hydraulic and thermal limits, and calculation of economics and other KPIs

- Performance Improvement (thermal and hydraulic) for the network over the next few months of operations with an number of Future Scenarios (alternative operational plans – e.g. cleaning schedule, flow splits), in particular trends towards hydraulic and thermal limits, and calculation of economics and other KPIs

- Recommended operation plan for the next months and assessment of benefits, including optimal operation of flow splits between branches