Nanocomposite Coating on Different Types of Heat Exchangers

Heat exchangers are vital components across numerous industries, facilitating thermal energy transfer between different environments. These devices are crucial in processes ranging from energy production to air conditioning, oil refining, and more. However, the efficiency and longevity of heat exchangers can be compromised by challenges such as corrosion, bio-fouling, and deposit accumulation. Oceanit’s HeatX, a revolutionary nanocomposite surface treatment, offers a groundbreaking solution to these issues, ensuring heat exchangers operate at their best for extended periods.

Understanding Heat Exchangers and Their Challenges

Heat exchangers come in various forms, each designed to meet specific operational needs. Despite their differences, all heat exchangers face common challenges that can severely impact their performance.

- 1. Shell-and-Tube Heat Exchangers

Shell-and-tube heat exchangers, commonly used in chemical processing and power generation industries, are known for their reliability and long service life. However, they can be prone to corrosion and are less efficient than other types, with heat transfer efficiency around 70%.

- 2. Plate Heat Exchangers

Plate heat exchangers are compact and highly efficient, with heat transfer rates up to 95%. They are easy to maintain but have a shorter service life due to frequent clogging, making them more suitable for applications requiring high efficiency in limited space.

- 3. Spiral Heat Exchangers

Thanks to their unique spiral design that minimizes scale build-up, spiral heat exchangers offer excellent performance in handling viscous and polluted fluids. However, the specialized manufacturing process makes them more expensive and less commonly available.

- 4. Spiral Tube Heat Exchangers

Spiral tube heat exchangers are compact, cost-effective, and capable of withstanding high pressures, making them ideal for small-capacity applications. Their main drawback is the limited availability and higher cost due to patented designs.

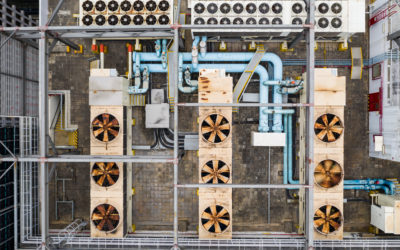

- 5. Air-Cooled Heat Exchangers

Air-cooled heat exchangers are ideal for regions with limited water availability, using ambient air to cool and condense fluids. While they eliminate the need for water, they require significant space and are more expensive due to their large size and structural requirements.

HeatX: The Nanocomposite Solution

Oceanit’s HeatX is an innovative nanocomposite surface treatment designed to address the challenges faced by various types of heat exchangers. Developed with support from the U.S. Department of Energy, HeatX enhances the performance and durability of heat exchangers and condensers by preventing bio-fouling and corrosion.

How HeatX Works

HeatX is an omniphobic coating that repels both oil and water, preventing organisms from adhering to surfaces and causing fouling. It creates an ultra-slick, low surface energy layer on the metallic surfaces of heat exchangers, making it highly effective without relying on harmful biocidal compounds. HeatX is non-insular, maintaining the heat transfer efficiency of exchangers with a functional thickness of less than two mil DFT.

HeatX+ for Condensers

A specialized variant, HeatX+, is designed specifically for condensers. It promotes efficient dropwise condensation, improving overall efficiency and reducing the need for frequent maintenance.

The Environmental and Economic Benefits

HeatX is a water-based, non-VOC, and non-toxic formulation that can be applied even to unprepared, corroded surfaces. This ease of application, combined with its long-lasting protective properties, makes HeatX a cost-effective solution for enhancing heat exchanger performance.

Maintaining the efficiency and durability of heat exchangers is crucial for reducing operational costs and minimizing environmental impact. HeatX nanocomposite surface treatment offers a revolutionary solution to the challenges of corrosion and fouling, ensuring that heat exchangers and condensers operate at optimal efficiency for extended periods. By investing in HeatX, industries can enhance the performance of their equipment while contributing to a more sustainable future. Connect with our experts to learn more about HeatX.