From Failure to Fortification: How HeatX Transforms SAGD Heat Exchanger Protection

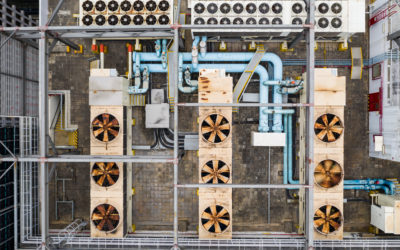

Steam-Assisted Gravity Drainage (SAGD) technology, often used in oil sand extraction, relies on the effective operation of heat exchangers. However, these systems are prone to significant corrosion issues, as highlighted by a case study of a SAGD facility in Alberta, Canada. The facility experienced two consecutive heat exchanger failures caused by corrosion due to high levels of dissolved oxygen in the boiler feedwater (BFW). These corrosion problems were exacerbated by low-flow conditions, allowing solids to accumulate in the system and leading to accelerated deterioration of the heat exchanger tubes.

This scenario underscores the importance of protective measures to avoid costly equipment failure, unscheduled maintenance, and environmental hazards. Had a protective coating like HeatX been applied, the situation might have been avoided. HeatX, a nanocomposite coating, provides a robust defense against corrosion by forming a durable barrier between the equipment’s metal surfaces and corrosive agents such as water and oxygen. This coating could have mitigated the corrosion risks caused by dissolved oxygen in the BFW and prevented the buildup of solids that contributed to the accelerated failure of the heat exchangers.

Why HeatX Could Have Helped

- Corrosion Resistance: HeatX provides a non-toxic, omniphobic surface that repels water, reducing the exposure of the metal surface to oxygen, water, and other corrosive substances.

- Durability in Harsh Environments: SAGD systems operate in high-temperature environments, which can exacerbate corrosion. HeatX’s robust thermal and mechanical properties are designed to withstand these tough conditions, providing long-lasting protection to heat exchangers and other critical components.

- Enhanced Flow Efficiency: By reducing the adhesion of solids and contaminants, HeatX could have helped prevent the accumulation of solids that occurred due to low flow conditions, thus maintaining the smooth operation of the heat exchangers and reducing wear and tear.

Cost Benefits

As seen in the Alberta case study, the cost of replacing failed heat exchangers, combined with plant downtime and potential environmental cleanup, can be astronomical. By applying a preventive solution like HeatX, companies can extend the lifespan of their equipment, minimize operational interruptions, and avoid the cascade of additional costs triggered by corrosion-related failures.

In the context of SAGD facilities and other high-temperature industrial processes, protecting heat exchangers from corrosion is essential for operational efficiency and cost savings. Solutions like HeatX offer advanced, reliable protection against the types of corrosion that typically plague such systems, ensuring the long-term success and sustainability of oil extraction operations. By investing in protective coatings, companies can prevent corrosion-related incidents, reducing downtime and extending the life of their equipment. Reach out to our experts to learn more about HeatX.