HeatX Increases Performance While Inhibiting Corrosion and Biofouling

This case study describes Oceanit’s program work with Hawaiian Electric Company’s (HECO) Kahe power plant on the west coast of Oahu (Figure 1). The Kahe plant uses seawater to cool operational fluids, leading to biofouling in operational heat exchangers.

The use of unprocessed water in HECO’s heat exchangers creates significant problems such as:

- Fouling and rapid growth of barnacles and other micro/macro organisms

- Tubular abrasion from sand carried in the sea water

- Erosion from scale particles breaking loose and impinging on other surfaces

- Corrosion of metal exchanger and shell components.

HECO was previously forced to take each heat exchanger unit offline every 3-6 months for major cleaning and maintenance work. HeatX surface treatment significantly reduced the frequency of shutdowns and maintenance required, while preserving heat transfer efficiency and allowing increased loads to be placed on a treated heat exchanger unit. HeatX saved a utility an estimated $360,000 on maintenance plus $1.5 million on replacement energy generation savings over a period of five years – per heat exchanger.

Figure 1: Kahe Power Plant (HECO)

Because HECO uses unprocessed seawater for cooling, before releasing it back in to the ocean, any coatings or materials are heavily regulated under federal and state laws. Coatings may not leach any harmful, biocidal, or toxic materials that could pose a threat to local marine life. The solution for these restrictions would ordinarily be to move to a high-cost CRA, such as titanium. In Oceanit’s application of HeatX, the subject heat exchangers at HECO had no coating or treatment other than a thick layer of epoxy to protect the stationary tube sheet from sand erosion. The epoxy coating, however, does not provide any fouling resistance. HeatX met the strict environmental regulations while providing the low surface energy, high pressure & temperature stability, and omniphobic properties well-suited for repelling and releasing biofouling.

HECO Heat Exchangers

The initial subject heat exchanger at HECO was a horizontal, 4-pass, TEMA type BEM (fixed tube sheet) containing approximately 1000 x .75” OD x 20’ long SA179 carbon steel tubes (Figure 2). It is one of a train of identical chillers fitted to the turbines at the power plant. In December 2016, the corroded exchangers were isolated, cleaned and one was treated on-site with HeatX surface treatment. For a period of six months after reintroduction into service, performance was closely monitored against identical, untreated chillers. As untreated heat exchangers’ performance started to falter, the HeatX unit showed no signs of deterioration.

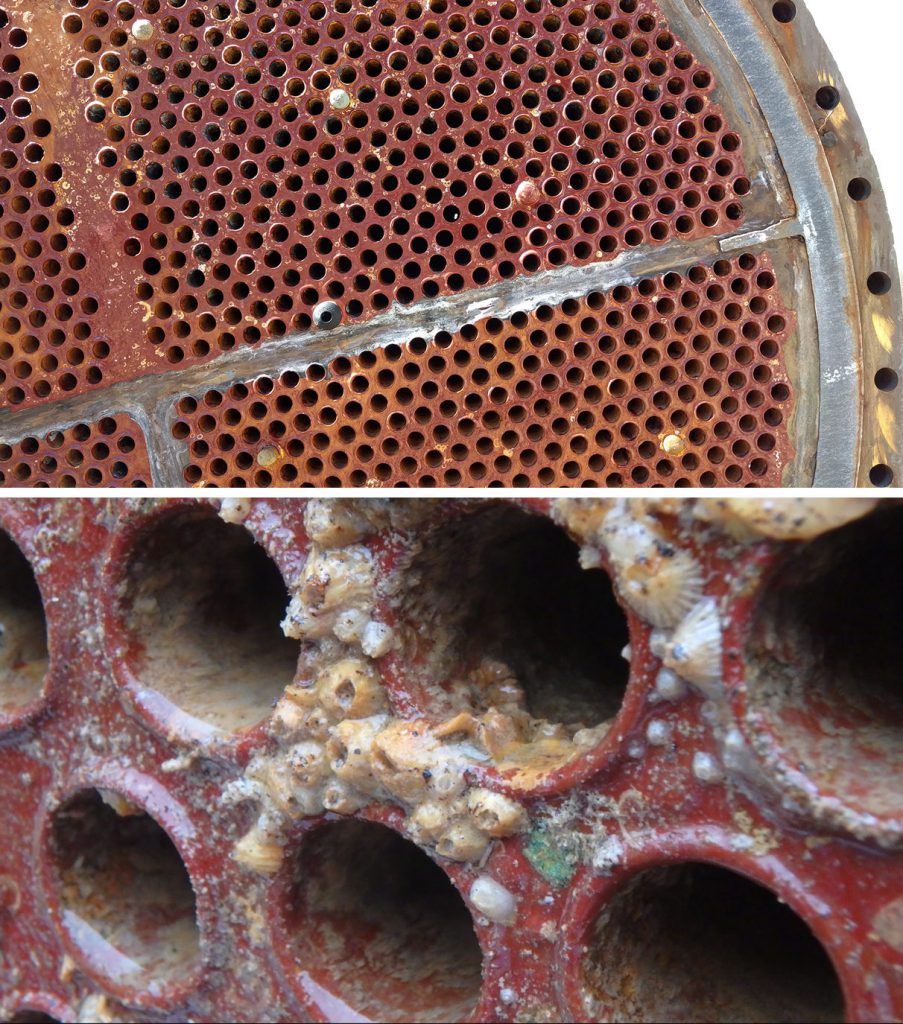

Figure 2: Shell and Tube heat exchanger at Kahe (HECO)

HeatX Performance

After six months, the units were again taken out of service for inspection, determined to be clean and immediately placed back into service. Figure 3 shows the same exchanger unit taken out of service at 26 months, again proving to be clean and functioning at optimal efficiency (Figure 3). The HeatX-treated unit showed no signs of blockage or fouling buildup during both inspections, unlike the non-treated units which had been cleaned at the same time in December 2016 and inspected at the typical six-month point (Figure 4). The untreated units had significant fouling and debris which had begun to affect performance, as was typical. The HeatX unit, needing no maintenance, was promptly put back into service. HeatX demonstrated low adhesion rates, high pressure stability, and high temperature stability. Due to the extreme low surface energy of the HeatX, the treated surface mitigated any significant formation of biofilms and prevented barnacles from taking hold on the exchanger.

Field Trial Evaluation

The HeatX-treated exchanger completed over 30 months of trouble-free service. HeatX enabled HECO to skip five heavy cleaning and maintenance cycles on the unit since December 2016, saving HECO significant downtimes, maintenance costs, and man hours.

During the initial six-month period, HECO monitored the seawater, auxiliary chiller water inlet & outlet temperature, and the overall power generation from the turbine associated with HeatX versus an untreated chiller. The six-month inspection showed a negligibly thin layer of biofilm and debris but no signs of blockage or barnacle build up.

The heat exchanger was removed from service for a visual inspection in January, 2019. A pressure wash with water easily cleared all debris from the tube sheet and visual inspection showed that HeatX was still fully functional. The unit is now being returned to service, still without any need for further cleaning or maintenance.

Downtime for heat exchanger maintenance was reduced from 20 days/ year to just 1 day/year with HeatX.

In addition, the HeatX-treated chiller was able to absorb all costs for replacement power generation when a non-treated chiller went out of operation – saving $15,000 per day by handling a load from two turbines at once.

Economic Impact of HeatX

HeatX coating addresses two major issues (i) reduces exchanger downtime & maintenance costs and (ii) mitigates the cost of replacement power generation during downtime. Based on the performance data and analyzing HECO’s cost associated with maintenance and replacement power generation, HECO estimates that HeatX will save nearly $72,000 per year per unit. For HECO’s Kahe power plant, when rolled out to all heat exchangers, this equals $1.5 Million or more in savings over a period of five years.