Boosting Heat Exchanger Efficiency with Hybrid Nanofluids: The HeatX Advantage

The demand for higher thermal efficiency in industrial processes has led to groundbreaking advancements in heat exchanger technologies. Among these innovations, hybrid nanofluids have emerged as a game-changing solution for improving thermal performance. These cutting-edge fluids, composed of multiple nanoparticles suspended in a base fluid, redefine the heat transfer limits. When paired with advanced surface treatments like HeatX, the potential for efficiency and longevity in heat exchangers reaches unparalleled levels.

What Are Hybrid Nanofluids?

Hybrid nanofluids combine two or more types of nanoparticles—such as metal oxides, carbides, or carbon nanotubes—dispersed in a carrier fluid like water, oil, or ethylene glycol. These nanoparticles significantly enhance the fluid’s thermal conductivity and heat transfer capabilities.

Key Benefits of Hybrid Nanofluids:

- Superior Heat Transfer: Their enhanced thermal conductivity allows for faster and more efficient heat transfer compared to traditional fluids.

- Reduced Fouling: Nanoparticles prevent scale and debris buildup, ensuring longer operational life for heat exchangers.

- Customizable Properties: Depending on the nanoparticles used, hybrid nanofluids can be tailored to meet specific thermal and operational needs.

Studies, such as those highlighted by SpringerLink, have demonstrated that hybrid nanofluids outperform single-component nanofluids in efficiency and stability.

How HeatX Maximizes the Potential of Hybrid Nanofluids

While hybrid nanofluids revolutionize the medium of heat transfer, HeatX transforms the surface where this heat exchange occurs. HeatX is an advanced surface treatment that optimizes the performance of heat exchangers, making it an ideal partner for hybrid nanofluids.

The HeatX Advantage:

- Enhanced Heat Transfer Surfaces: HeatX reduces surface roughness and improves the thermal conductivity of heat exchangers, amplifying the benefits of hybrid nanofluids.

- Corrosion Resistance: By protecting against corrosion and chemical degradation, HeatX ensures the longevity of equipment operating with these advanced fluids.

- Eco-Friendly Operations: Combining HeatX with hybrid nanofluids reduces energy consumption and carbon emissions, supporting sustainability goals.

- Maintenance Reduction: The anti-fouling properties of HeatX and hybrid nanofluids work in tandem to minimize downtime and maintenance costs.

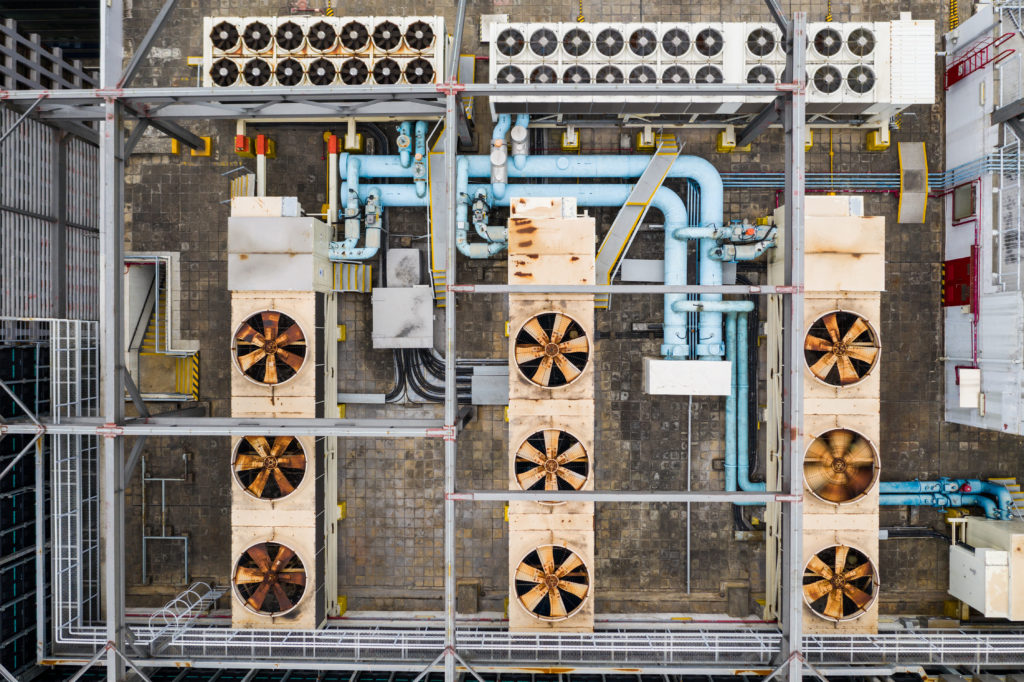

Applications in Industry

1. Power Generation:

Hybrid nanofluids are increasingly used in cooling systems for thermal and nuclear power plants. When paired with HeatX-treated heat exchangers, power plants can operate more efficiently while reducing wear and tear on critical components.

2. HVAC Systems:

The HVAC industry benefits from the superior heat transfer capabilities of hybrid nanofluids. HeatX enhances its application by preventing corrosion and scale buildup, leading to more reliable climate control systems.

3. Manufacturing:

Industries reliant on process heating and cooling, such as chemical and food processing, gain substantial energy savings and operational reliability with the HeatX-hybrid nanofluid combination.

Why This Innovation Matters Now

The need for sustainable and efficient industrial operations has never been greater. Hybrid nanofluids represent a leap forward in thermal management, but their full potential is unlocked only when paired with cutting-edge technologies like HeatX. Together, they offer a comprehensive solution to meet the increasing demands for energy efficiency, reduced environmental impact, and cost savings.

The integration of hybrid nanofluids and HeatX offers a transformative approach to heat exchanger efficiency. By leveraging the enhanced properties of these nanofluids and the protective, performance-boosting qualities of HeatX, industries can achieve greater productivity while safeguarding their investments.

As industries strive to meet modern efficiency and sustainability standards, the adoption of innovative solutions like HeatX and hybrid nanofluids will define the future of heat exchanger technology. Learn more about HeatX with our experts.