Extending Lifespan and Efficiency of HeatX in Seawater-Fed Heat Exchangers

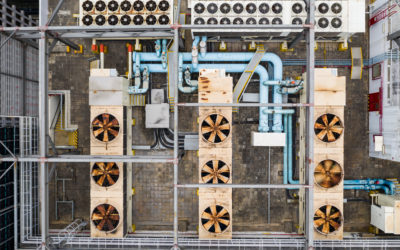

Seawater-fed heat exchangers are widely used in coastal power plants and refineries. They are an economical and efficient method of cooling, taking advantage of the free and abundant seawater available. However, these systems face several challenges that compromise efficiency and lifespan. Fouling is one of the most significant issues, which occurs when biofilms, mineral deposits, and other materials accumulate on the heat exchanger’s surfaces.

The Challenges of Using Seawater-Fed Heat Exchangers

Seawater-fed heat exchangers are constantly exposed to a variety of marine elements, which can lead to several problems:

- Biofouling: The buildup of biological material, such as algae, bacteria, and other microorganisms, can quickly clog up the heat exchanger. This reduces efficiency by restricting the flow of water and impeding heat transfer.

- Corrosion: Seawater is highly corrosive, especially when combined with biological material. Over time, constant exposure to salt and marine organisms can degrade the heat exchanger’s metal components.

- Scaling and Erosion: Minerals in the seawater, such as calcium and magnesium, can crystallize and form deposits on the heat exchanger’s surface. This buildup reduces heat transfer efficiency and contributes to erosion as the solid particles wear away from the surface.

Given these issues, engineers must carefully consider the design and materials used in seawater-fed heat exchangers to mitigate fouling and corrosion. However, post-installation strategies are often necessary to address fouling and corrosion after the heat exchanger has been in use.

HeatX Nano-Surface Treatment: A Game-Changer for Heat Exchangers

Oceanit Laboratories’ HeatX nano-surface treatment (NST) provides an innovative solution to many of the problems faced by seawater-fed heat exchangers. HeatX is a nanocomposite surface treatment specifically designed to protect against corrosion and fouling. It can be applied to both new and existing systems, making it a versatile option for various industries.

Here’s how HeatX addresses the challenges:

- Prevents Biofouling: The ultra-low surface roughness created by HeatX makes it difficult for biofilms and other biological materials to adhere to the heat exchanger’s surfaces. This reduces the accumulation of harmful biological materials, allowing for smoother water flow and better heat transfer.

- Protects Against Corrosion: The harsh marine environment accelerates corrosion in seawater-fed heat exchangers. HeatX forms a protective barrier between the metal surface and the seawater, preventing corrosion from degrading the system over time. By reducing corrosion, HeatX extends the lifespan of the heat exchanger.

- Reduces Scaling: Scaling is a common issue in seawater-fed systems due to the high mineral content in seawater. The hydrophobic properties of HeatX minimize the adhesion of minerals, significantly reducing the scaling rate.

- Easy Application and Durability: One of the key advantages of HeatX is that it requires minimal surface preparation and can be applied quickly, even to systems that are already in use. Once applied, it cures atmospheric conditions and provides long-lasting protection. In fact, studies have shown that heat exchangers treated with HeatX can operate for up to 24 months without any signs of fouling or corrosion.

How HeatX Boosts Operational Efficiency

HeatX helps keep heat exchangers operating at optimal efficiency for longer periods by minimizing biofouling, corrosion, and scaling. Reduced fouling means the heat exchanger can transfer heat more effectively, allowing for greater energy efficiency. This also reduces the need for frequent cleaning and maintenance, leading to significant cost savings for operators.

Additionally, by extending the lifespan of heat exchangers, HeatX reduces the need for costly replacements and repairs. It also helps companies avoid the downtime and lost revenue that come with heat exchanger failure or degradation.

Seawater-fed heat exchangers are an efficient and cost-effective solution for coastal industries, but they come with significant challenges. Fouling, corrosion, and scaling can all reduce efficiency and shorten the lifespan of these systems. However, with HeatX nano-surface treatment, companies can protect their heat exchangers from the harsh marine environment, reducing fouling, preventing corrosion, and extending the life of the equipment. Investing in HeatX is a smart choice for companies looking to maximize the performance and longevity of their seawater-fed heat exchangers. Reach out to our experts to learn more about HeatX.